WUXI NOVA PERTOEUM Multistage Horizontal Pump is a cost-effective, low-maintenance solution for high-volume, high-pressure fluid movement.

COMPONENTS:

Pumps, Thrust chamber, Intake, Discharge, control, instruments, Skid, and Motors.

The Wuxi Nova MHP is engineered for oil & gas and mining with modular design, pre-aligned skid, and API 610-capable alternatives.

The standard construction material for the impeller and diffuser is ASTM A436 Ni-Resist Type 1 with high-nickel iron, offering excellent corrosion and erosion resistance.

For severe environments, optional Tungsten Carbide radially stabilized materials, corrosion-resistant alloys, or component hardening are available.

Due to limited diameters, each stage develops low head. Stages are stacked to meet lift requirements. The rotating impeller adds velocity via centrifugal force. The stationary diffuser converts velocity to pressure and acts as a bearing surface for shaft stability.

Standard Shaft: High-strength K-500 Monel

Optional: 17-4PH, Nitronic 50, Inconel

WUXI NOVA PERTOEUM Unique Thrust chamber — the most reliable in the industry. All impellers fixed to shaft act as a single body.

All thrust is carried by external bearing chamber — no axial contact between impellers and diffusers during operation.

Discharge flange bolted to pump head, sealed with O-rings.

Standard: ISO or ANSI flange

Sizes: 4", 6", 8", 10", 12"

Pressure: Up to 5000 PSI

Steel I-Beam base plate with pump supports, painted. Delivered fully mounted.

No field alignment required

All components serviceable on location

For low-head: three-phase induction, 2-pole @ 3600 rpm

For high-head: 4-pole motors

Motors directly coupled to thrust chamber.

Most selected: TEFC

Optional: Gas/diesel engines (2:1 gearbox)

Switches and/or sight glasses provide monitoring functions.

Internal Polymer coating and tungsten carbide bearings available on request to improve reliability and prevent premature failure from corrosion.

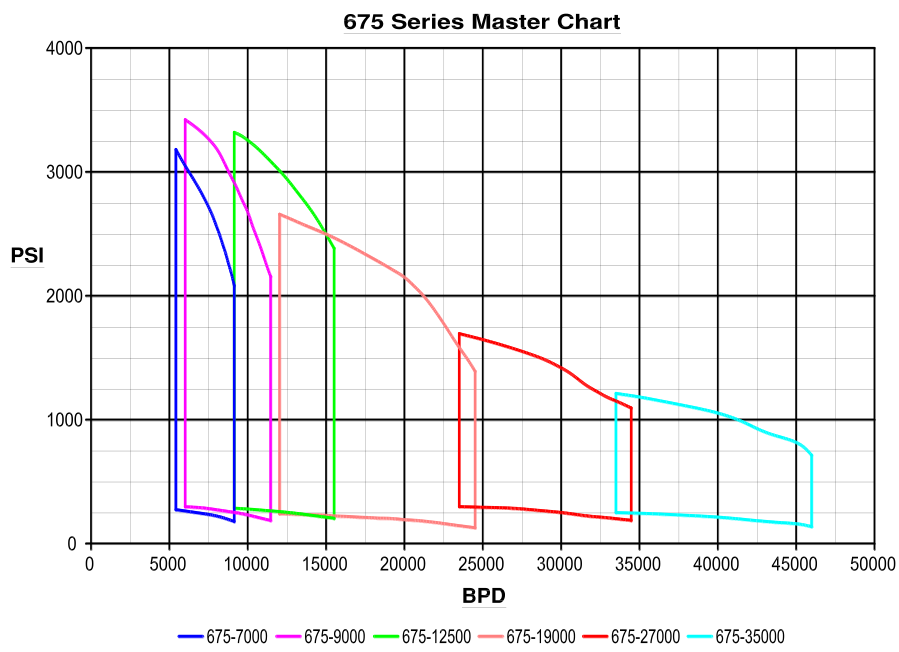

| Type | Min. B/D | BEP B/D | Max B/D | Stages Max | Pressure Max | Shaft HP |

|---|---|---|---|---|---|---|

| 675-7000 | 5500 | 6800 | 9000 | 53 | 4550 | 1250 |

| 675-9000 | 6000 | 8800 | 11500 | 53 | 4200 | 1250 |

| 675-12500 | 9000 | 11500 | 15500 | 48 | 4000 | 1250 |

| 675-19000 | 12500 | 19500 | 25000 | 44 | 2750 | 1250 |

| 675-27000 | 23500 | 28000 | 34500 | 40 | 2700 | 1250 |

| 675-35000 | 33500 | 40000 | 46000 | 32 | 2500 | 1250 |

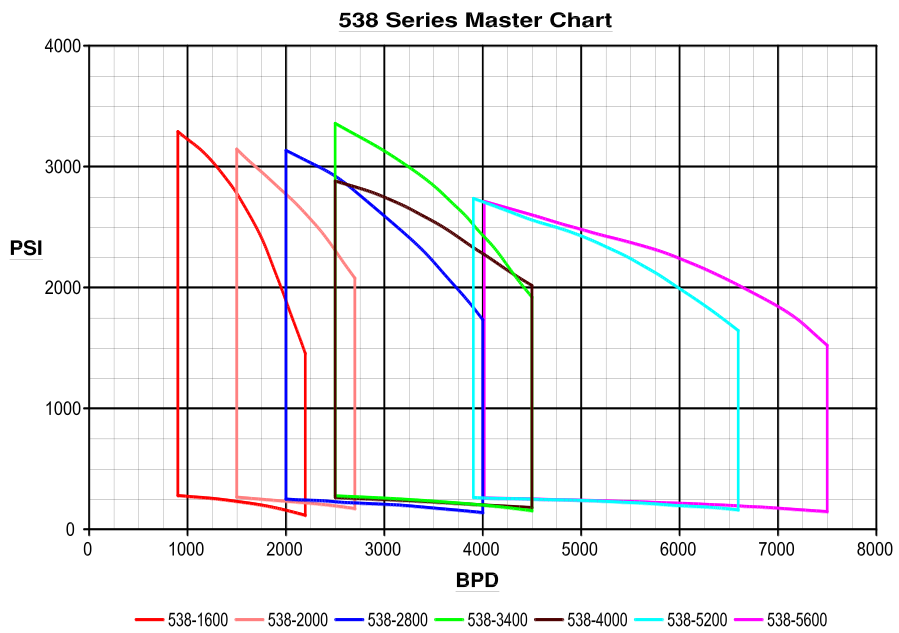

| Type | Min. B/D | BEP B/D | Max B/D | Stages Max | Pressure Max | Shaft HP |

|---|---|---|---|---|---|---|

| 538-1600 | 1100 | 1550 | 2000 | 272 | 6000 | 1000 |

| 538-2000 | 1700 | 2200 | 2700 | 251 | 6000 | 1000 |

| 538-2800 | 2000 | 3000 | 4000 | 196 | 6000 | 1000 |

| 538-3400 | 2500 | 3500 | 4500 | 179 | 6000 | 1000 |

| 538-4000 | 3500 | 4500 | 5500 | 100 | 4000 | 1000 |

| 538-5200 | 3900 | 5250 | 6600 | 68 | 4000 | 1000 |

| 538-5600 | 4000 | 5750 | 7500 | 68 | 4000 | 1000 |

| 538-7000 | 5000 | 7000 | 9000 | 68 | 4000 | 1000 |

| 538-10000 | 7000 | 9500 | 12000 | 68 | 4000 | 1000 |

Ask the representative for more lists of the pumps. 12-inch impellers and diffusers are also available in exceptional cases.

Engineered for Oil & Gas and Mining industries:

WUXI NOVA PERTOEUM strives to provide high-quality, innovative, safe, and environmentally sound solutions through advanced technologies, strict quality management, and superior engineering.

Leader in Horizontal system testing. Detailed QA/QC program meets or exceeds petroleum industry demands. Aggressive testing ensures API compliance.

Email your specs — get a custom solution in 24 hours

API-Certified • H₂S Ready • 12-Month Warranty • Global Delivery

Get MHP Quote