Wellhead and control systems are essential in various industries for monitoring and controlling production

processes.

They consist of components such as sensors, transmitters, controllers, and displays, which

work together

to ensure precise control of variables like flow, temperature, and pressure. This field,

known as

instrumentation and control engineering, focuses on the design and implementation of

systems that measure

and control these process variables.

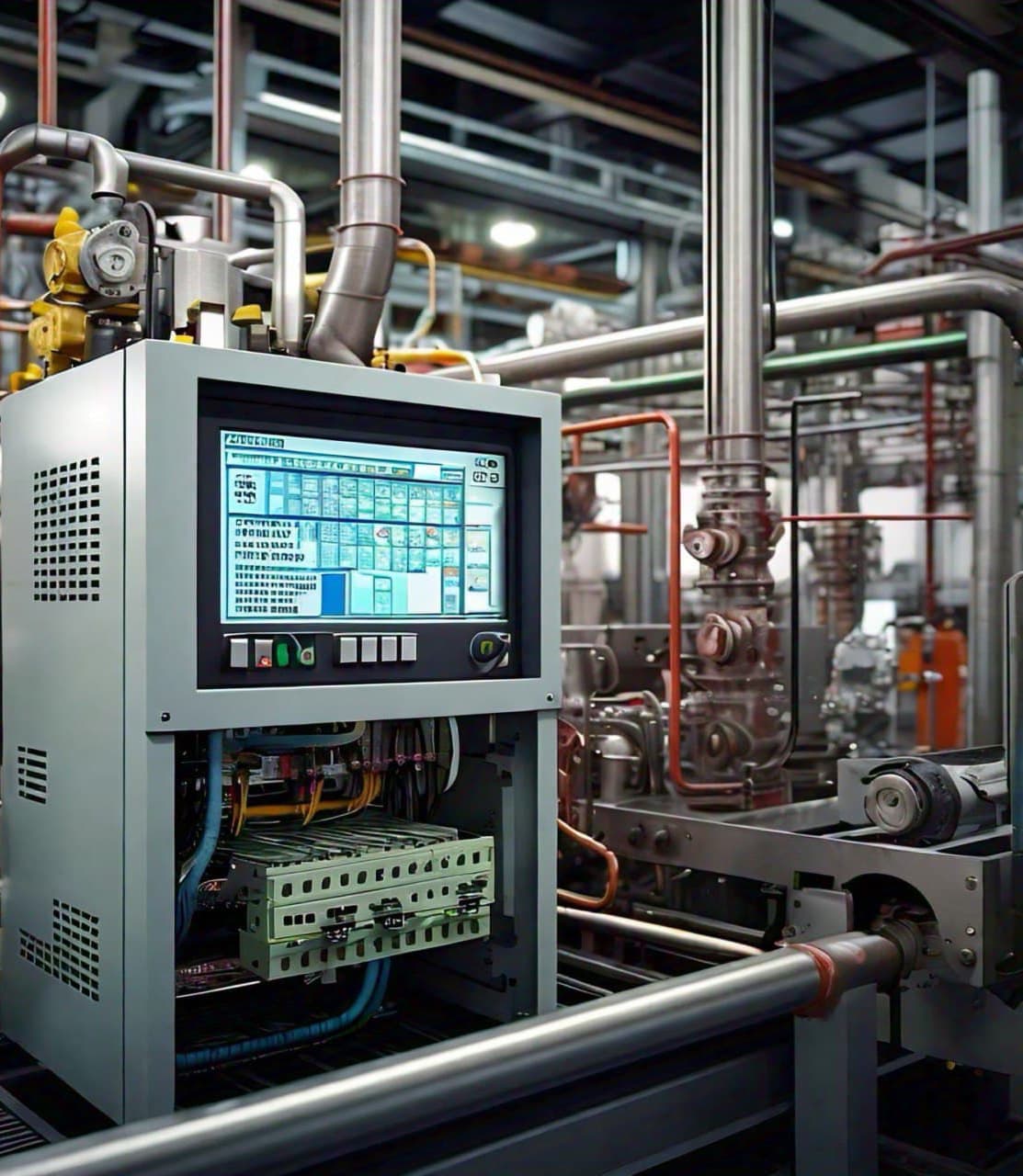

Standard systems used in this field include PLC (Programmable Logic Controller),

DCS (Distributed Control System), RTU (Remote Terminal Unit), and

SCADA (Supervisory Control and Data Acquisition).

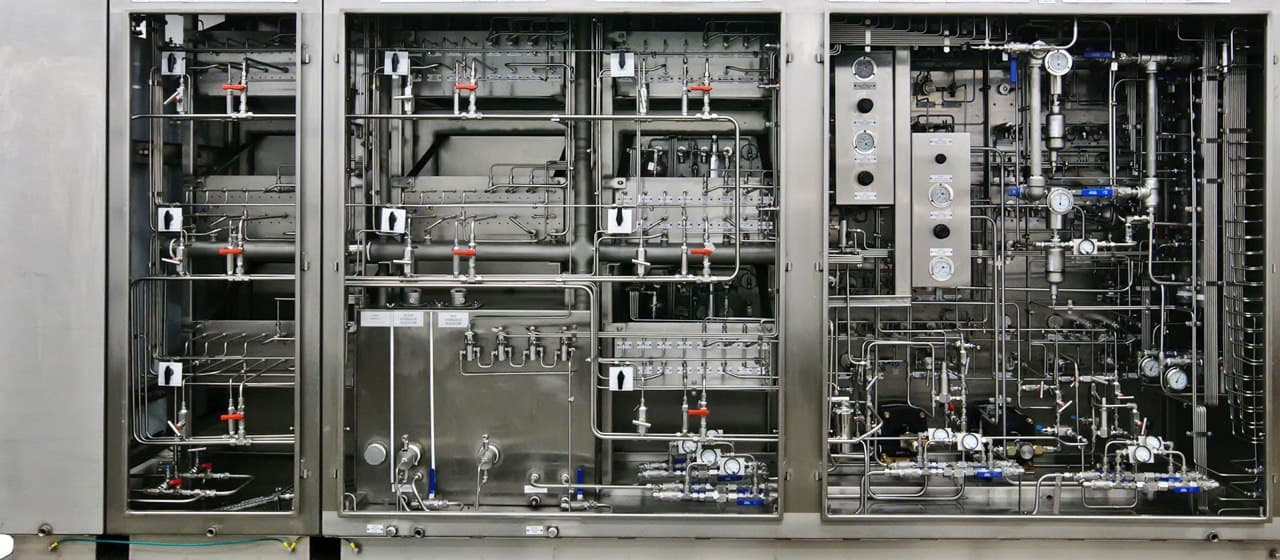

WHCPs — also known as Shutdown Panels (SDP), Emergency Shutdown

Systems (ESD),

or Hydraulic Safety Shutdown Systems (HSSS) — are fail-safe shutdown

systems with

pneumatic/hydraulic/electric components. They can be integrated with PLCs, RTUs, and SCADA

systems

and serve as both standalone control systems and interfaces between the plant

control system and the wellhead safety system.

WHCPs are used for monitoring, controlling (Remote/Local), and safe shutdown of Subsurface

Controlled Safety Valves (SCSSV), Surface Safety Valves (SSV), and other

wellhead safety valves (Choke, ESD, HIPPS) in oil & gas production fields to ensure safe operation of

unattended wells/platforms.

Single Well

Single Well