Multiphase pumping has become a critical component in many production schemes. Far from being a niche technology, it is fast becoming a standard component of the modern oil and gas production system. Multiphase pumps provide cost savings and operation flexibility in applications as diverse as onshore heavy oil and subsea/offshore conventional oil.

A PCP is a positive displacement pump consisting of a single winding rotor with a round cross-section and a stationary stator. We at WUXI NOVA PETROLEUM SERVICES provide a complete solution for the design and supply of all components for Multiphase Applications.

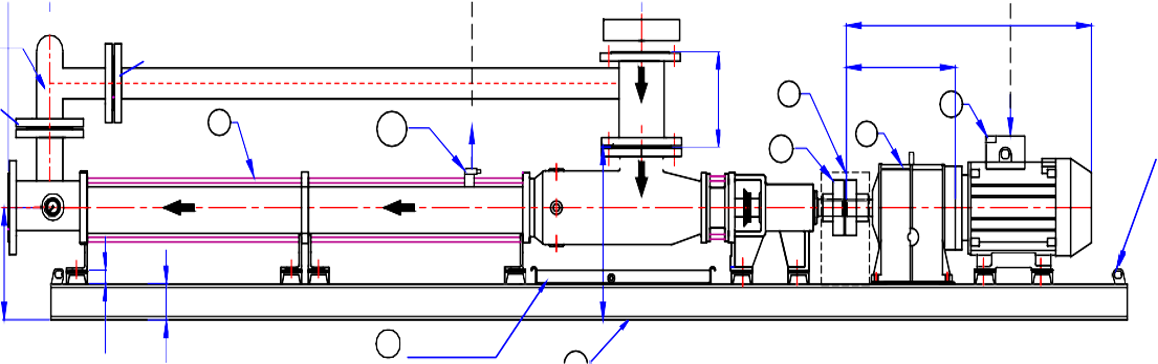

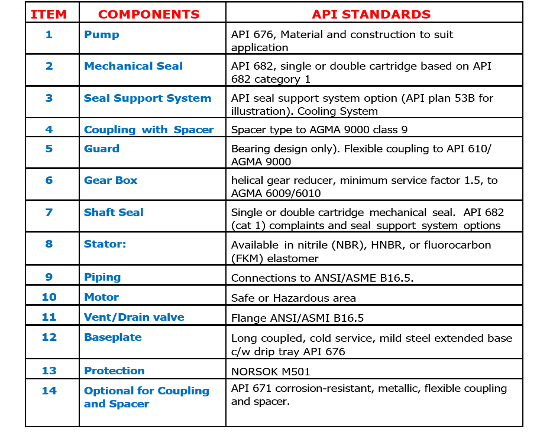

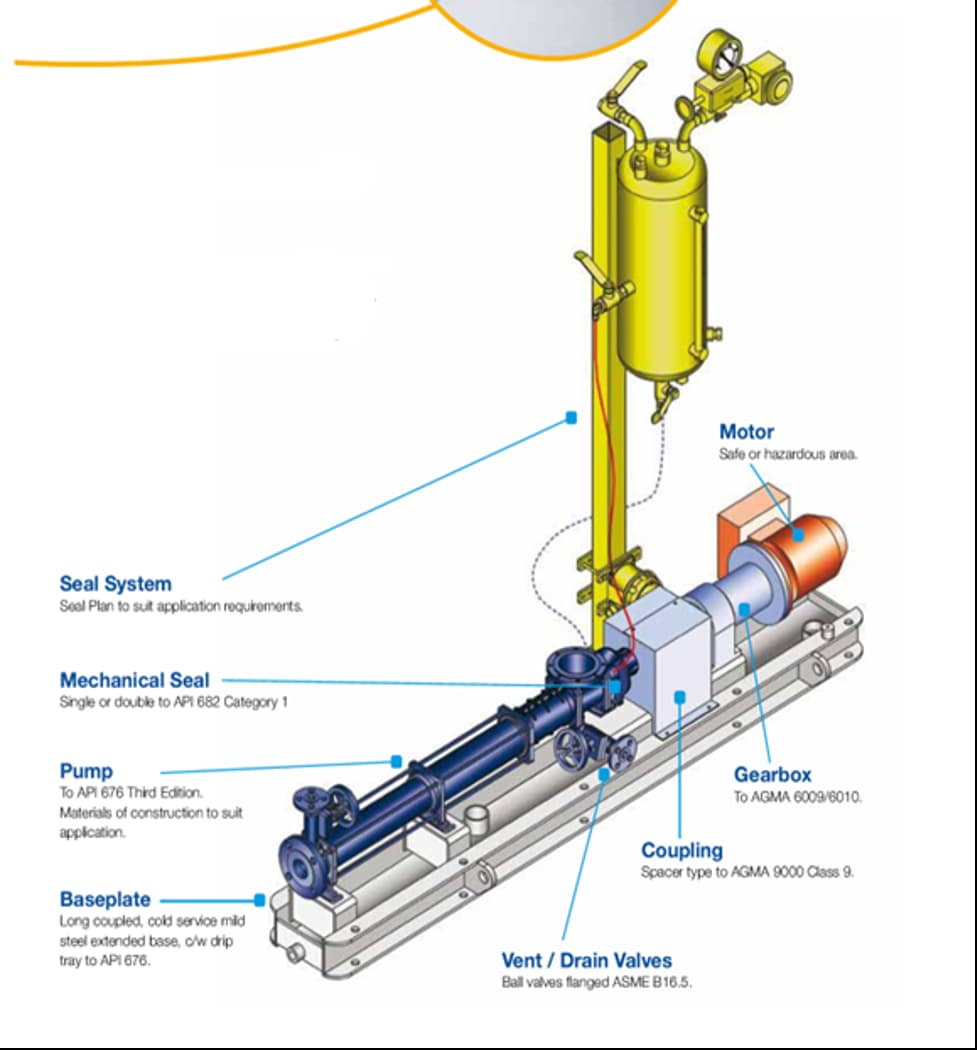

We supply all equipment, including Skid Mounted, Pump (consistent stator, Rotor), Fixed Speed or Variable Speed Drive, Gearbox, Electric Motor, Junction Box, surface electrical, and unique control system. We have established alliances with leading manufacturers to produce PCP at a very robust and very affordable price compared to others.

WUXI NOVA PETROLEUM SERVICES offers a full suite of application-specific equipment to meet your Multiphase Surface PCP needs.

Through continuous research and development, we strive to create innovative tools that deliver greater value to oil and gas production companies.

Boosting Wells into High-Pressure Gathering System

Multiphase Surface PCPs have all been used in different countries to boost production from low-pressure

wells into higher-pressure gathering systems. As an alternative to installing vessels and conventional gas

compression.

Recommended API Standard: API 676 (3rd Edition) — details below.

The WUXI NOVA Multiphase progressing cavity pump technology brings multiple benefits:

WUXI NOVA's multiphase booster pump system can provide incremental oil production from naturally flowing or gas-lifted ESP wells, improve efficiency, and reduce operating costs.

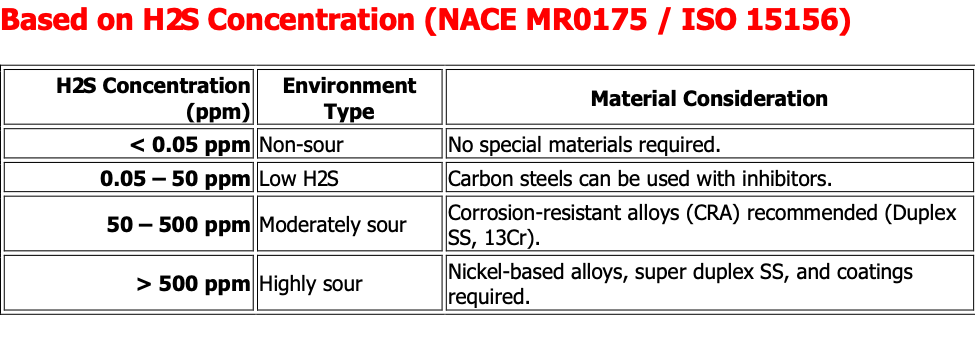

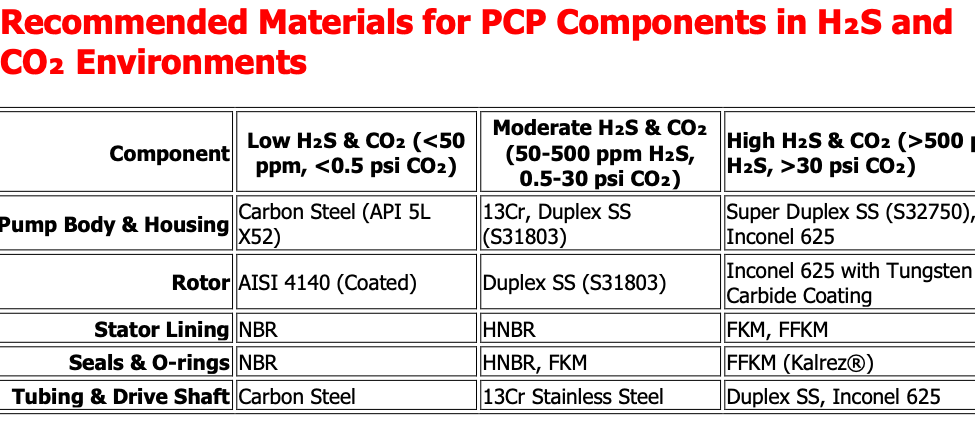

Chemical inhibitors and material science to combat H₂S and CO₂ degradation.

Wear is proportional to speed. PCP excels when PSI > GPM.

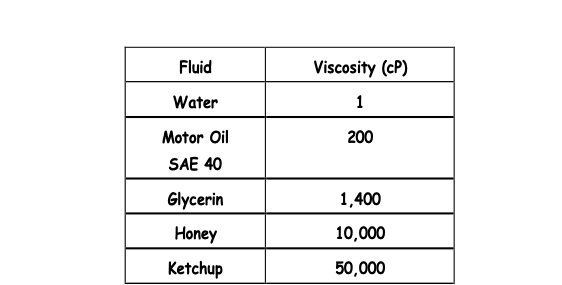

The more viscous a fluid, the slower the pump must run to allow it to flow into the cavity. At reduced speeds, the pump may not develop 100% volumetric efficiency, and has to be considered for the selection process.

As a rule of thumb, the PC Pump is an efficient choice when the required pressure exceeds the flow rate (PSI > GPM).

It is prudent to address the significant concerns in the selection process: abrasion, temperature,

and viscosity.

Wear is proportional to speed, especially in a PC pump.

Below are shown some Viscosity Indications: [Performance curves available on request]

API 676 | Global delivery | Full after-sales support