Premium Industrial Heat Exchangers – Built for Performance and Longevity

Optimize your process with our high‑efficiency Shell & Tube, Plate, and Air‑Cooled Heat Exchangers, engineered for demanding oil & gas, petrochemical, power, and water treatment applications.

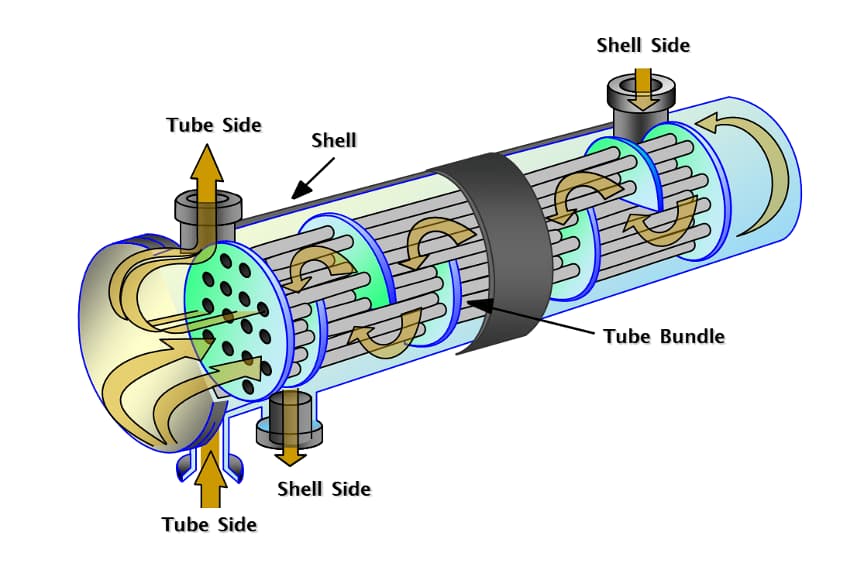

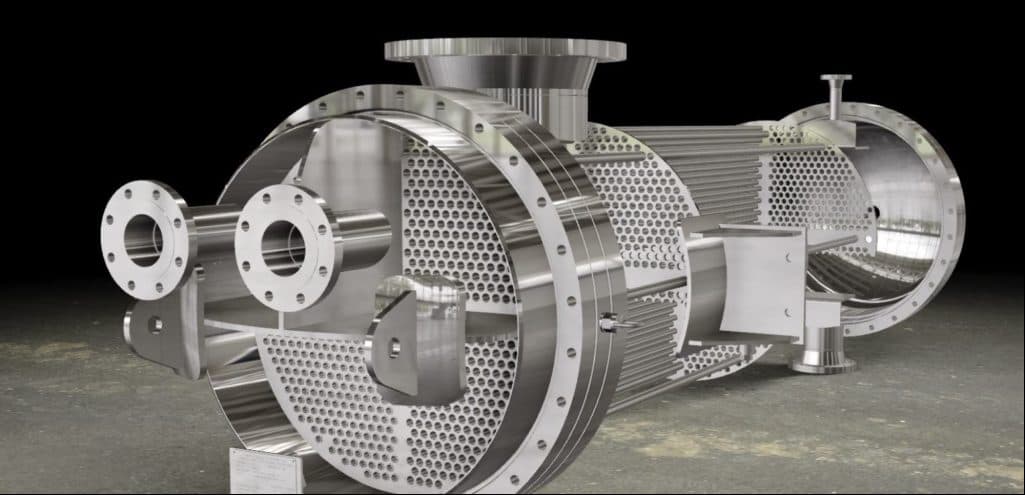

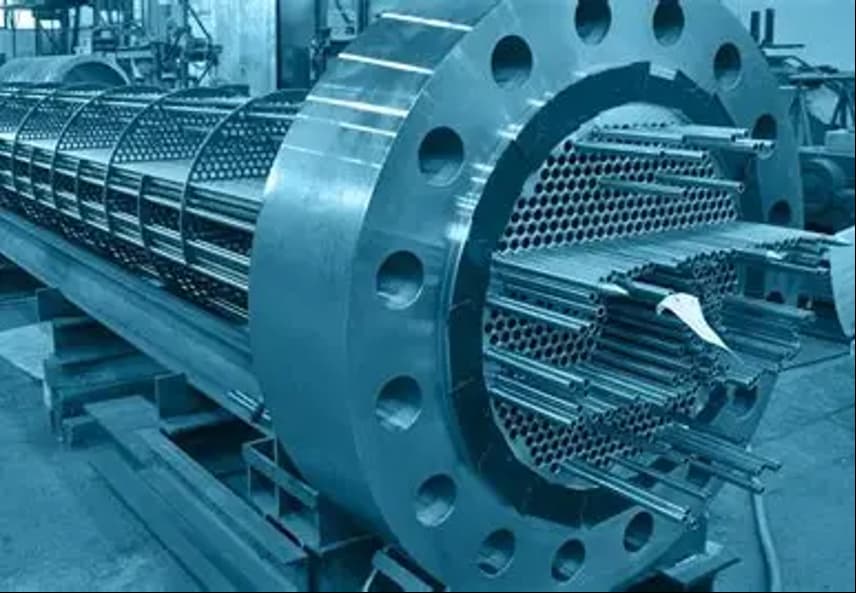

The most widely used type in the oil & gas industry — robust, reliable, and compliant.

Robust construction handles extreme temperatures and pressures. Available in fixed tube sheet, U‑tube, and floating head designs.

Compact, efficient, and modular — perfect for clean fluids and tight spaces.

Gasketed, brazed, or welded plate designs offer superior heat‑transfer coefficients and minimal footprint.

Zero water usage — ideal for remote and arid environments.

Forced or induced‑draft fin‑fan coolers eliminate water usage. Perfect for remote locations, gas turbine exhaust cooling, and compressor inter/aftercoolers.

Engineered for performance, compliance, and durability in extreme conditions.

Compact design maximizes heat transfer while minimizing footprint and energy loss.

Designed per ASME, TEMA, API 660, API 662.

Stainless Steel, Alloy 20, Duplex, Titanium, Carbon Steel — tailored to your fluid and environment.

Multiple applications including but not limited to:

Crude Oil Heating & Cooling

Gas Dehydration & Compression

Water Treatment & Condensate Recovery

Chemical & Process Industries

From design to delivery — we deliver precision, reliability, and support.

In‑house design and thermal simulation using HTRI & Aspen

ISO 9001 certified manufacturing with full material traceability

Fast delivery with global logistics and on‑site technical support

Tailored designs to meet your exact process conditions and space constraints

ASME / TEMA / API Certified | Global Delivery | Full After-Sales Support

Protect your pumps, turbines, and systems with precision-engineered strainers designed for oil, gas, and petrochemical applications.

An oil strainer is a filtering device used to remove solid particles, debris, and contaminants from oil before it enters critical equipment such as pumps, compressors, turbines, or lubrication systems. Its primary purpose is to protect downstream components from wear, clogging, or damage.

1. Suction Strainer

Installed at the inlet (suction side) of pumps.

Prevents large debris from entering the pump.

Typically has a coarse mesh (e.g., 40–100 mesh).

Engineered for reliability in continuous and high-flow operations

Built to global standards for pressure, temperature, and durability

| Parameter | Typical Range / Note |

|---|---|

| Material | Carbon steel, stainless steel, bronze |

| Mesh size | 40 to 200 mesh, depending on oil cleanliness |

| Pressure rating | 150 – 2500 Class (ASME B16.5 standards) |

| Temperature range | Up to 400°C (depending on oil type) |

| Connections | Flanged, threaded, or welded ends |

| Cleaning type | Manual (removable screen) or automatic (self-cleaning) |

Critical protection across oilfield and industrial systems

Lubrication systems in turbines, compressors, or gearboxes

Fuel oil lines for engines and burners

Hydraulic oil circuits

Pump suction protection

Refineries and petrochemical plants

Keep your strainers performing at peak efficiency

Periodically remove and clean the screen/basket

Inspect for clogging, corrosion, or mesh damage

Install pressure gauges or differential pressure indicators

API-Certified | Global Delivery | 24-Hour Response | Full After-Sales Support